5 minutes read

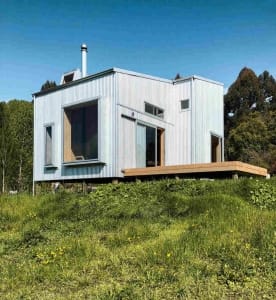

Somewhere along the winding roads between Auckland and Wellington, two architects stumbled upon a ridge above Taihape that would quietly transform into a beacon of thoughtful design. What began as a roadside discovery evolved into the AB Cabin — a modest yet striking retreat shaped by the latest in prefab construction techniques, and grounded in a deep reverence for place.

The AB Cabin was awarded the 2019 Western Architecture Award in the Small Project Architecture category by the New Zealand Institute of Architects.

Rethinking Building from the Ground Up

When architects Ainsley O’Connell and Barry Copeland first envisioned this remote escape, they weren’t just designing a holiday home—they were prototyping a smarter way to build. Located five hours from their main office in Auckland, the site demanded a building strategy that minimized construction time on site and offered greater control.

Their solution? Embrace prefabrication. By shifting much of the labor and precision work offsite, they could streamline the build process without sacrificing design integrity.

Rather than relying on traditional construction methods, this cabin leverages the precision of industrialized building techniques to respond to both logistical constraints and a commitment to sustainability. But what truly sets it apart is how these high-tech methods support a deeply personal, handcrafted experience of home.

The Beauty of Cross-Laminated Timber

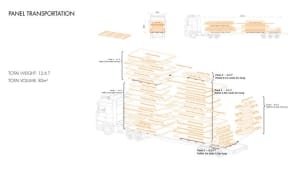

Central to the AB Cabin’s success is its use of Cross-Laminated Timber (CLT). These engineered wood panels are strong, renewable, and thermally efficient. But beyond their performance, they offer a natural aesthetic warmth that elevates the living experience.

Inside the cabin, the CLT is left exposed. The result is a tactile interior rich with grain, scent, and subtle light play. It brings a feeling of calm and groundedness, reminding occupants they are surrounded by a material that once stood as a forest.

These panels were precisely fabricated, numbered, and delivered in a single shipment. Within two days, the structure was erected; in just over a week, it was weatherproof and ready for finishing.

Save Hours of Online Research

Use our free quote comparison tool. Upload the details of your project and receive proposals from our network of manufacturers.

COMPARE QUOTESFrom Prototype to Possibility

The AB Cabin wasn’t just a design project — it became a testbed for future housing solutions. As New Zealand continues to grapple with a growing housing shortage, Copeland sees this project as an example of how offsite construction and locally sourced materials can offer scalable, affordable alternatives.

But the beauty lies in how the home doesn’t feel mass-produced. Instead, it exudes character. For example, every offcut from the CLT panels was repurposed. From cabinetry to benches and even an observation turret in the loft, nothing went to waste. This level of intention transforms what could be purely functional into something poetic.

Compact Living, Expansive Experience

With just 725 square feet to work with, the layout needed to be smart, fluid, and adaptable. And it delivers.

The main space serves multiple purposes: it’s a studio for creative work, a living area for relaxation, and a space to gather. Above, a mezzanine sleeping platform offers privacy while maintaining a connection to the rest of the cabin. Adjacent to the main room is a service spine that includes a bathroom and storage, topped by a flexible loft with a cozy lookout.

Clever spatial design and generous window openings make the space feel far larger than its footprint suggests. Whether hosting family or retreating alone, the cabin flexes to suit the moment.

Designed for the Land and the Climate

The AB Cabin sits lightly on its site. Supported by timber posts, it avoids heavy excavation and minimizes impact on the land. Large windows open the interior to stunning views of the Ruahine Ranges and the ever-shifting skies above Taihape.

The building envelope, meanwhile, is fine-tuned for performance. CLT’s natural thermal mass, paired with high-quality insulation and ventilated glazing, ensures year-round comfort. The home is heated with locally sourced firewood, reinforcing its low-impact ethos.

Even the cladding tells a story. Wrapped in corrugated metal, the cabin echoes the rural barns and sheds that dot the landscape — a subtle nod to local vernacular architecture, updated with a contemporary twist.

Get quotes for your prefab project

Take 5 minutes to complete our form and receive quotes from our network of prefab suppliers. It's free, quick, and easy.

ASK FOR QUOTESA Connection That Goes Beyond the Physical

What resonates most about the AB Cabin is its emotional footprint. This isn’t just about construction systems or energy performance. It’s about how architecture can support a lifestyle grounded in presence, slowness, and connection.

The cabin’s owners, who designed it for their own use, speak fondly of the rhythms of the place. Of neighbors who bring fruit from their orchards. Of distant trains that pass in the night. Of light that shifts across the valley each hour.

This isn’t a sterile prefab shell. It’s a space filled with memory, atmosphere, and invitation.

What We Can Learn from the AB Cabin

The AB Cabin is a powerful reminder that industrialized construction doesn’t mean impersonal. When applied with care and vision, these techniques can create homes that are efficient, affordable, and deeply human.

- Prefabrication reduces construction time, waste, and environmental impact.

- Materials like CLT blend high performance with aesthetic richness.

- Smart spatial planning can make small spaces feel generous and flexible.

- Architecture can tell stories—about place, material, and intention.

In a world facing both environmental and housing crises, projects like this offer a roadmap forward.

Want to Go Deeper?

Explore more of our insights into the future of building:

- The Ultimate Guide to Prefabricated Housing

- Sustainable Construction Methods

- What are Eco Friendly Prefab Homes

Photos Paul McCredies